Where the IMPOSSIBLE becomes POSSIBLE

We live our projects as a challenge that leads us to achieve “IM POSSIBLE” goals

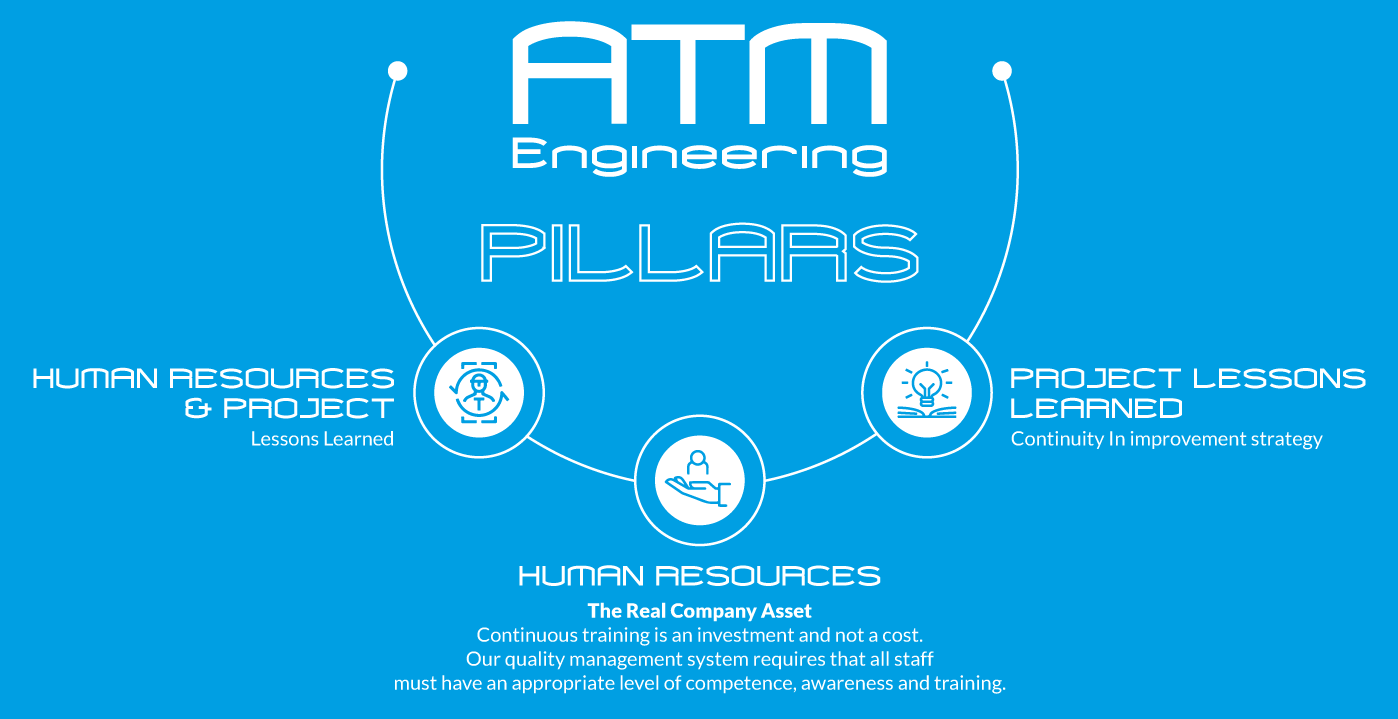

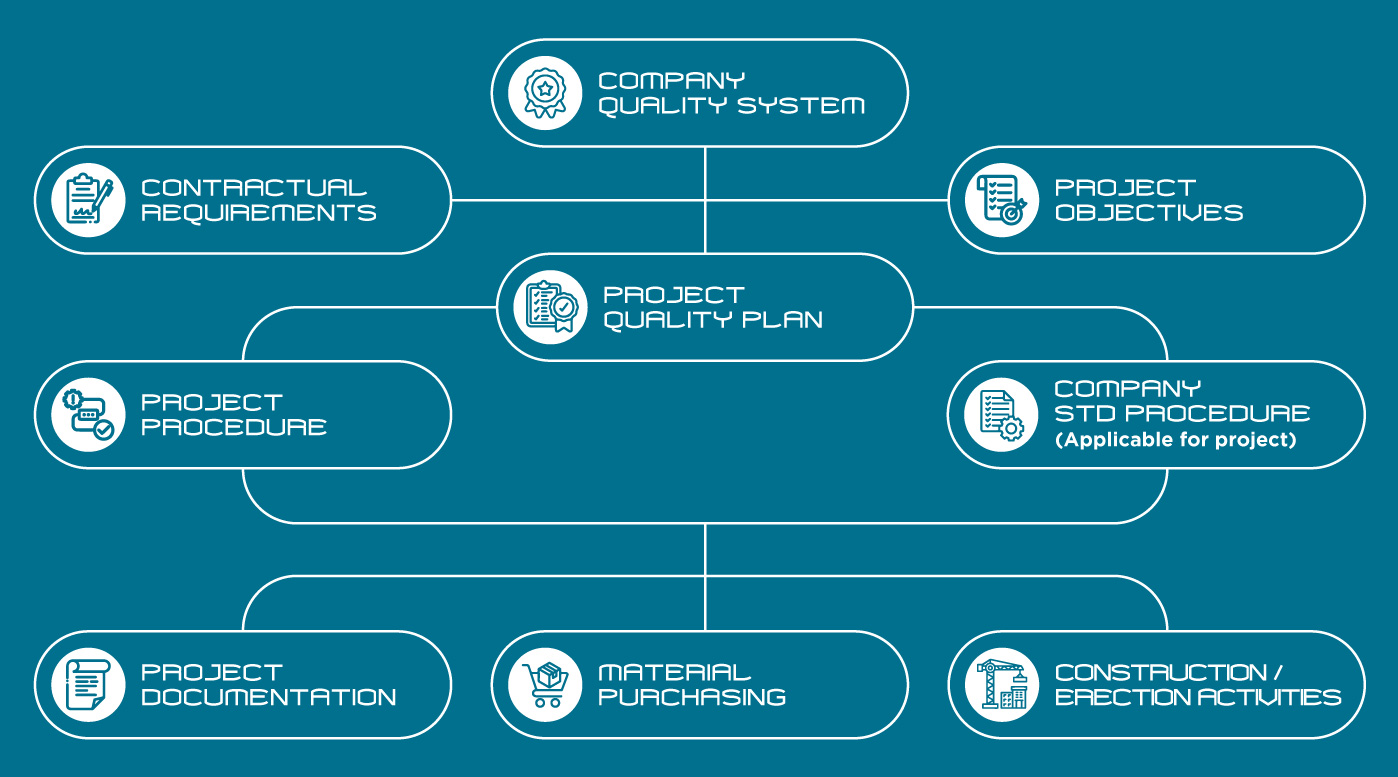

We have created a structured work in progress that, within our Company, influence the quality of our services, namely: the organization of the Company itself, the procedures, staff training, the tools used and their maintenance, the work environment, etc. according to ISO 9001 2015.

Starting from this standard, our quality system can be partially modified to adapt to the contractual requirements assumed for a specific Project.

It is the policy of A.T.M. to ensure that all personnel involved in activities influencing the quality of the company’s organization and executive projects have an adequate level of competence, awareness, and training.

In fact, our personnel are continuously instructed and trained by internal tutors with proven experience of over 40 years in services carried out within one of the largest international General Contractor groups, to ensure compliance with the contractual requirements of executive projects.

We do not judge our people by their mistakes but by their willingness to remedy them.

We do not judge our people by their mistakes but by their willingness to remedy them.

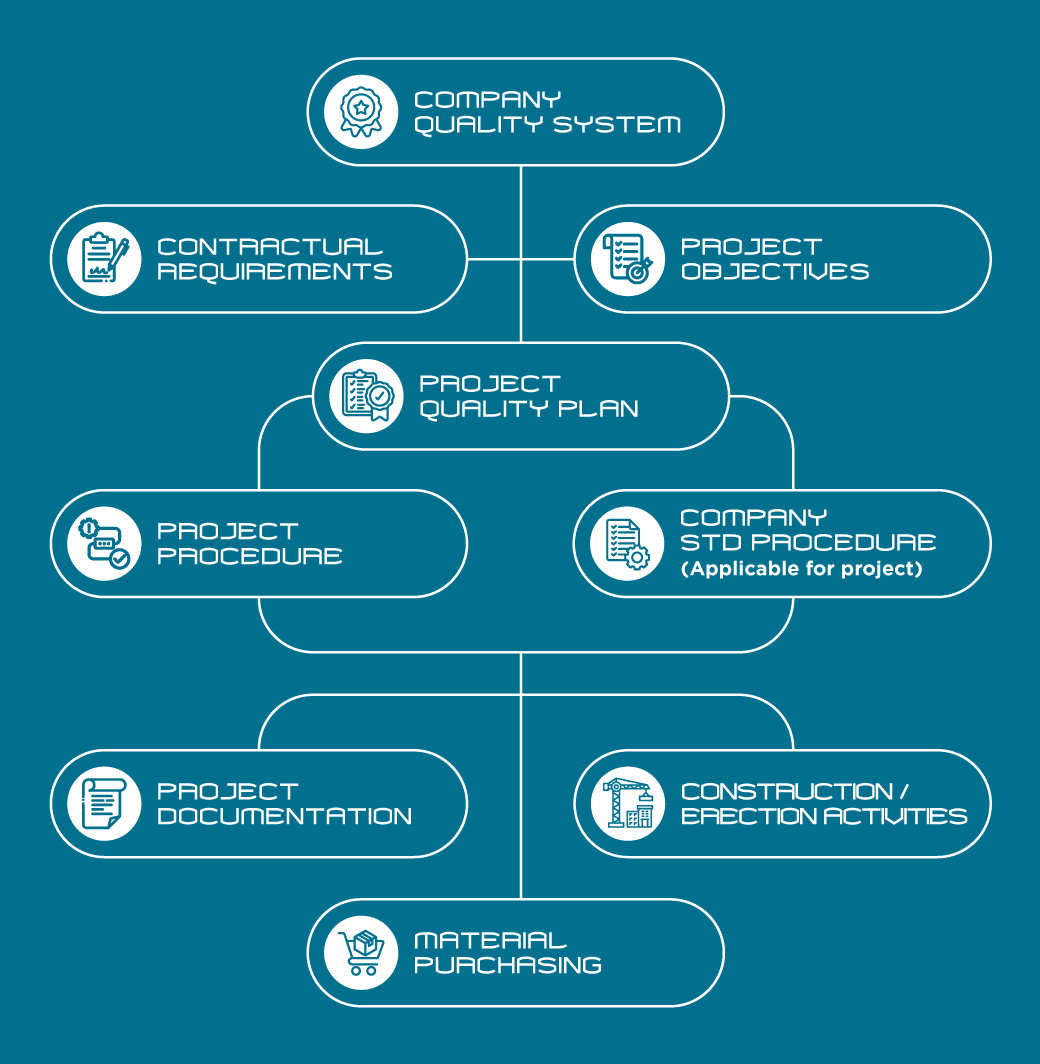

The procedures to be applied to the project consist of both standard documents, which originate from the company quality system, and specific procedures developed for the project, which are summarized in a Project Quality Manual. As shown here below

Once the scope of work, related criticalities, project constraints, contractual milestones and target milestones are defined, it is possible to prepare Overall Master Project Schedule to identify: Critical Path – Critical Activities – Non-Critical Activities.

The estimate accuracy depends on what stage the design has reached at the time the estimate is made, and on the reliability of the data available on equipment costs. Our cost estimating department is referred to AACE (Association for the advancement of cost Engineering) community as guidelines for applying the general principles of estimate classification to project cost estimates.

Below we report in simplified form the setting according to the AACE:

• Feasibility Study Phase: accuracy ±30%

• FEED (Front End Engineering Design) Phase: accuracy ±10%

• Extended FEED Phase: accuracy ±3%

For each project, activities are carried out by A.T.M. experts under the supervision of the Project Manager to fully meet the contractual requirements of the client.

For each project, we perform:

• Feasibility Study Phase: accuracy ±30%

• FEED (Front End Engineering Design) Phase: accuracy ±10%

• Extended FEED Phase: accuracy ±3%

During the project’s lifetime uncertain factors may jeopardize scope of work – Schedule – Budget. Therefore, especially for large size projects, a project risk analysis should be carried out to identify of potential risk areas and planning of proper countermeasure” Just in case”.

Project Management

Quality Management

Is leading group of people and processes and coordinating disciplines involved along project phases in the aim of reaching technical and financial objectives on time to meet client expectation.

Project Control

A) From planning perspective

- 90 day schedule must be produced

- WBS and overall schedule must be developed

B) From cost control perspective

- Efficient roll-up of costs by main category of expenses

- Effective cost and accounting reconciliation

Cost Control

- Transfer the estimating file into the reference budget

- Cost controller will monitor costs at all times and prepare the forecast on monthly basis

Risk Management

Assessment to identify

- Uncertainties

- Constraints

- Have long ter, view of the project, anticipating and developing appropriate plans